Magnetic Level Indicator Liquid Level Gauge Float Level Switches Float Level Transmitter

Tank level gauge for liquids-High pressure magnetic level indicator-level meter- rigid gauge-head Series UHC type magnet;

Basic Info

| Model NO. | UHC-C |

| IP Rating | IP68 |

| Certification | ISO |

| Customized | Customized |

| Fluid Type | Corrosive Fluid Level |

| Corrosive Material | ABS Anticorrosive Material |

| Corrosive Material 2 | PTFE Line Level Gauge |

| Kind | Float |

| Structure | All in One |

| Range | 0-10m |

| Principle | Magnetic Sensors |

| Transport Package | wooden cases or carton |

| Specification | ANSI, DIN, JIS, VW or others |

| Trademark | U-ideal |

| Origin | China |

| HS Code | 90261000 |

| Production Capacity | 300pcs/month |

Product Description

Tank level gauge for liquids-High pressure magnetic level indicator-level meter- rigid gauge-head

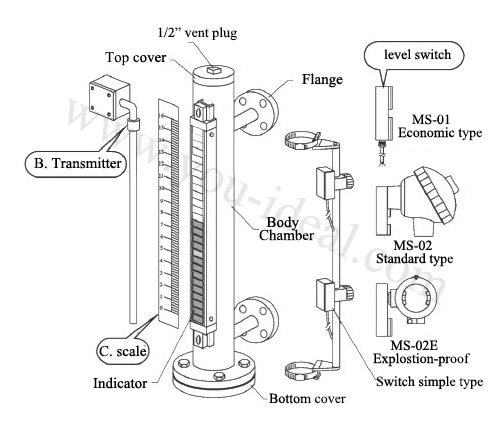

Series UHC type magnetic level gauges have been used by many enterprises of all walks of chemical, industries, petroleum, electricity, food, light, medicine, metallurgy, papermaking etc to measure the fluid level in pressure container and flammable and toxic liquid in opening container. Not only can display directly in field by two colors, but also can added upper and lower point alarming and control equipments, and that can realize the control and alarm function to the liquid in boiler automatically. This type level gauges can also connect with UR type transducer to realize remote digital analogy display and 4~20mA output signal.

How Magnetic Level Indicators Work

The UHC magnetic level gauge incorporates a float which contains an integral magnet. The buoyant float rises and falls with the liquid or interface level whilst the magnet 'flips' the indication mounted externally to the chamber. The white and red indication flaps represent air and liquid or the interface level respectively.

The magnetic level gauge can be mounted in various orientations, typically onto the side or top of a vessel.

Magnet System

Each of the coloured flaps contains a small magnet which rotates through 180o when passed by the bar magnet within the float. The bar magnet design does not lose magnetic field strength even at temperatures of 450oC, guaranteeing continuous operation in the most extreme applications.

The indication rail magnetic field is interlocked by the individual magnets in each of the flaps, which ensures a good indication under the most severe operating conditions such as vibration, fast changes in liquid level (surging) and de-gassing / boiling of the product.

Floats

UHC Floats are specifically calibrated to match the conditions of the vessel. The density, operating pressure and temperature are taken into account, ensuring that the inferred level is accurate and repeatable.

Floats material: SUS304, SUS316, PTFE, PP, Titanium.

Anticorrosive material: such as stainless steel SUS 304 or SUS316L, Teflon PTFE, polypropylene (PP), FRP and advanced tech. application such as X-ray detection, cold-rolling broaching weld, all ensure that the product can be adapted to any demand at site. Additional blow off valve can be added onto the bottom sealing type of the tube when necessary. Customized product is available for various types of special specifications.

UHC-C type Side Mounted Bi-color Magnetic Level Gauges

UHC-D type Top Mounted Bi-color Magnetic Level Gauges

UHC-B type Steam Jacket Bi-color Magnetic Level Gauges

UHC-F type Glass Fiber Reinforced Plastic Bi-color Magnetic Level Gauges

UHC-G type Boiler Special Using Bi-color Magnetic Level Gauges

UHC-Y type Electric Remote Reading Bi-color Magnetic Level Gauges.

| 1. Vent valve: to prevent the false liquid level, vent valve can be installed to the meter. And for the boiler specially using type it is not necessary to install the vent valve. 2. Blowout valve: in order to vent, sampling, drain and clean, other type valves also can be installed. 3. Up and low limit point alarming system: to control the limit level of upper point and low point. 4.heating and cooling system : in the circumstances of high temperature or low temperature, inlet steam or cooled water to control the flowing fluid temperature. 5.insulating sheath tube connecting size ; 1/2 " tube tread; steam heater pressure: ≤ 0.39 |

You may also like

Send inquiry

Send now